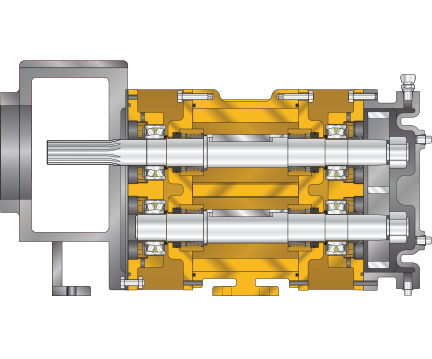

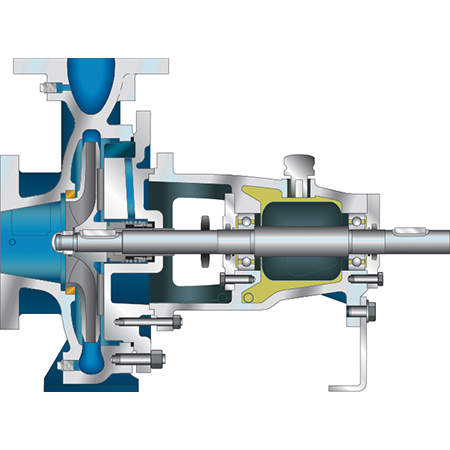

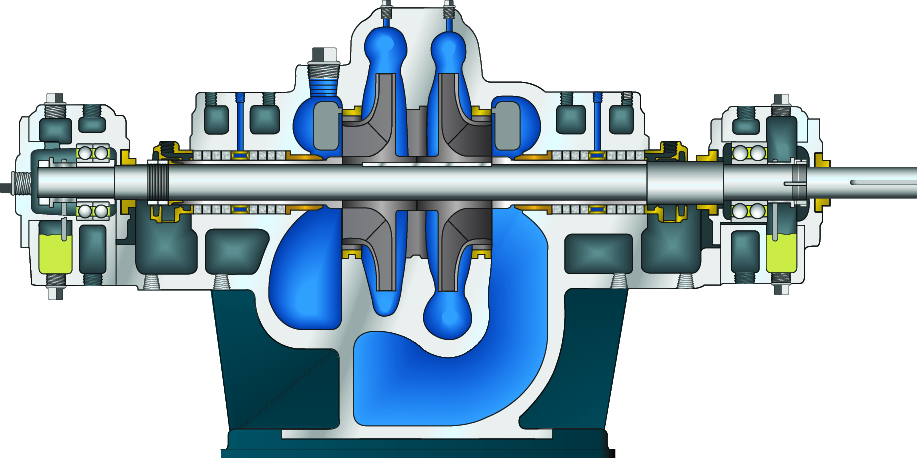

304 stainless steel flush tubing and ball valves

Tongue and groove bronze throat bushings

420 stainless steel shaft with 304 stainless steel shaft sleeves and lock nuts

Packing with lantern ring supplied standard with options for component or cartridge mechanical seals

Bearing isolators keep contaminants out of each bearing housing

Tongue and groove case wear rings and stage piece

Investment cast, 304 stainless steel, impellers

Bolt on bearing housings with register fit

Heavy wall, ASTM A48 class 30 cast iron casing assembly

400# suction and discharge flanges

Ring oiled, double row bearing housings with full 360 degree circumferential cooling jacket

Jacketed packing housing for high temperature applications

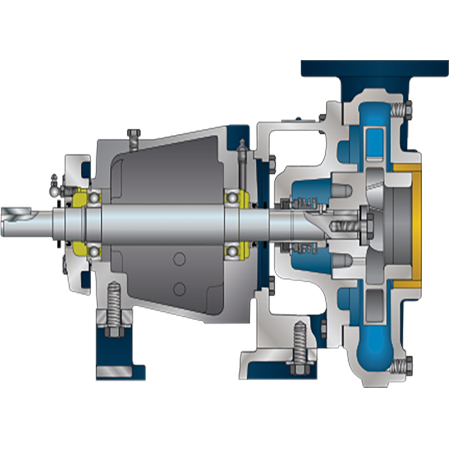

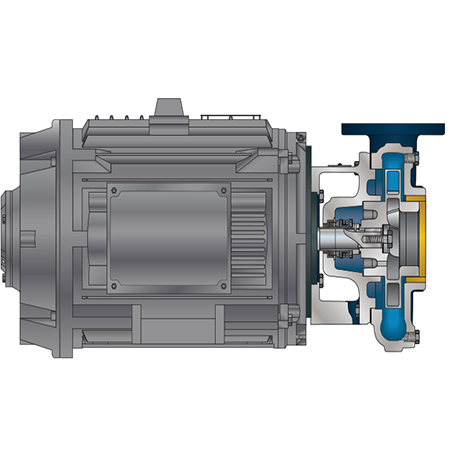

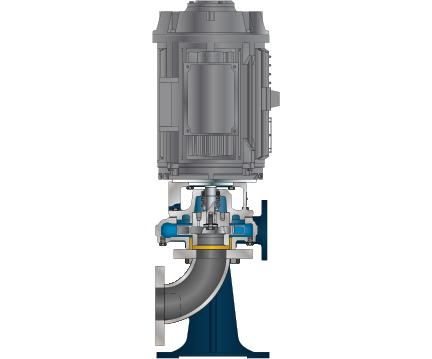

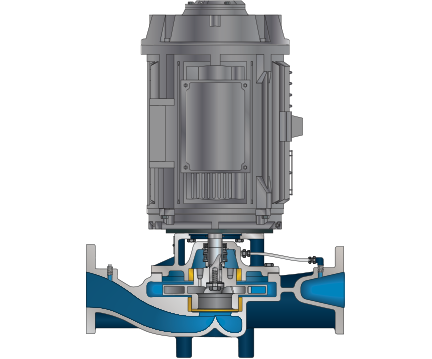

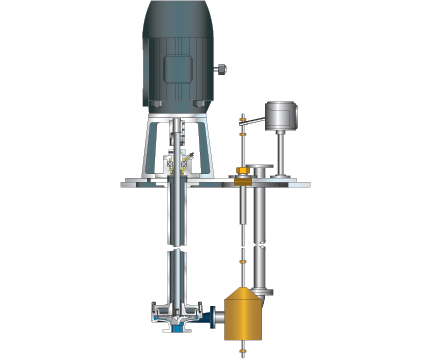

Series 3620 HM(2)

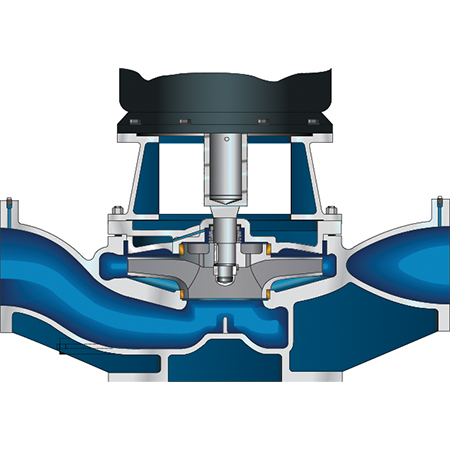

Two Stage Split Case Pumps

FEATURES & BENEFITS

The Series 3620 HM(2) Two Stage Split Case product line is a complete split case offering with a very diverse flow and pressure envelop in a very heavy duty design. This product can be electrically or Diesel engine driven and is a perfect fit for commercial, industrial and municipal applications.

Performance:

Flows: To 1,400 GPM [318 M3/HR]

Heads: To 1,250 FEET [381 M]

Speeds: 3550 RPM, 2950 RPM

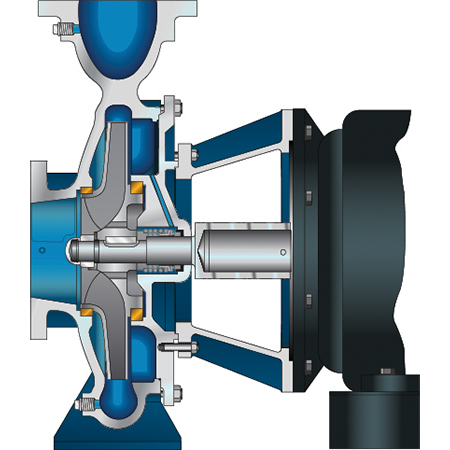

The 3620 Series HS(2) Two Stage Split Case product line has the following specifiable features and benefits:

- ASTM A48 class 30 cast iron casing with 400 PSI pressure ratings

- Opposed, Francis impeller design to reduce axial loads

- 400# suction & discharge flanges (optional RF flanges)

- High efficiency impeller design that lead the industry on lower horsepower

- Investment cast, 304 stainless steel impeller

- 420 stainless steel shafting

- 304 stainless steel shaft sleeves, 304 stainless steel glands and 304 stainless steel lantern rings

- 304 stainless steel flush lines with 304 stainless steel ball valves

- 5300 & 7300 series deep groove bearing at the inboard and outboard locations

- Modular rotating assembly groups minimizes number of parts needed

- Inboard & outboard bearing housings are removable and replaceable without removing the casing top

- Jacketed stuffing boxes for high temperature applications

- Jacketed bearing housings with ring oiled bearing lubrication