Ameriflo Tier 0 FM Approval

Ameriflo FM Diesel Engine Approval

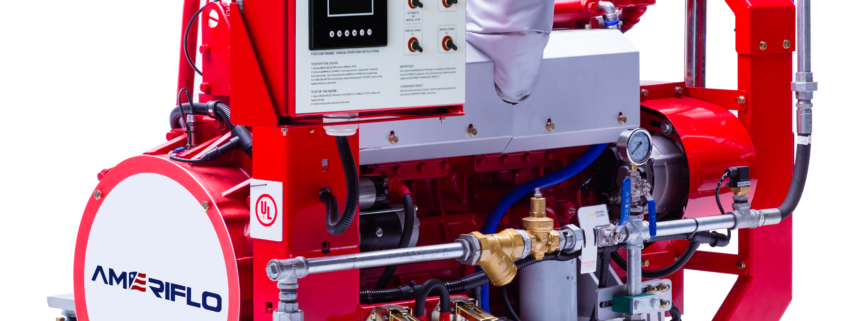

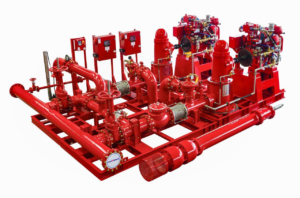

After over a year of intensive product development and an extremely stringent testing schedule, Ameriflo is proud to announce it’s Factory Mutual (FM) approval of the 9050 Diesel Engine program. This Factory Mutual approval covers the first 15 Ameriflo Diesel engines from 121 HP through an incredible 1207 horsepower. Speed ranges from 2950 RPM down through 1460 RPM. An additional 12 Diesel engines are going through final FM testing to have a total of 24 Diesel engines with Factory Mutual approval.

The Ameriflo Diesel engine is the most diverse and efficient Diesel engine product line available today. The Diesel engine group has spent considerable time developing blocks with a horsepower range that is simply not available from the competition. Ameriflo already has nearly 30 Diesel engines that are UL Listed and the FM approval adds to the heritage of this product line.

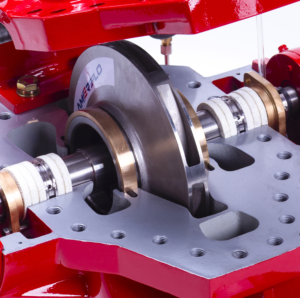

Ameriflo Diesel engines have features that the other Diesel engine manufactures simply do not have. The Diesel engine cradle is a unique and specifiable feature by virtually eliminating Diesel engine vibration that was historically transferred to the pump and system piping. The Diesel engine cradle also houses the emergency contractors, complete cooling loop and the Diesel engine pre-heater. The Ameriflo Vibration Isolation Cradle (VIC) has integral engine mounts that completely isolate the Diesel engine vibration from being transferred to the pump base assembly, This is a feature that no other Diesel engine manufacturer has. This VIC greatly reduces oscillations found from other Diesel engine manufacturers and allows all Ameriflo pump assemblies to operate vibration free.

Ameriflo Diesel engines have features that the other Diesel engine manufactures simply do not have. The Diesel engine cradle is a unique and specifiable feature by virtually eliminating Diesel engine vibration that was historically transferred to the pump and system piping. The Diesel engine cradle also houses the emergency contractors, complete cooling loop and the Diesel engine pre-heater. The Ameriflo Vibration Isolation Cradle (VIC) has integral engine mounts that completely isolate the Diesel engine vibration from being transferred to the pump base assembly, This is a feature that no other Diesel engine manufacturer has. This VIC greatly reduces oscillations found from other Diesel engine manufacturers and allows all Ameriflo pump assemblies to operate vibration free.

The Ameritouch digital engine controller has no “old school” gauges present. The end user is presented with a fully digital, touch screen interface that is state of the art! All Diesel engine parameters can be monitored from this digital interface making startup and run tests very easy. This is yet another example of how Ameriflo is leveraging technology to be the leader in the fire protection market.

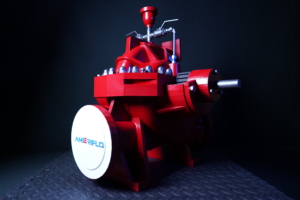

The 3D models that Ameriflo uses in engineering, during training events or at trade shows allows for an incredibly easy and lightweight manner to show off the state-of-the-art products currently offered by Ameriflo. These pumps are printed to scale (1:4) and allow for a very easy way to show off all of the standard feature and benefits that Ameriflo has worked so hard to create. As an example, these highly detailed samples show all of the acorn nuts, jackscrew and alignment pins as well as the complete flush plan system. Very clean and super cool……..

The 3D models that Ameriflo uses in engineering, during training events or at trade shows allows for an incredibly easy and lightweight manner to show off the state-of-the-art products currently offered by Ameriflo. These pumps are printed to scale (1:4) and allow for a very easy way to show off all of the standard feature and benefits that Ameriflo has worked so hard to create. As an example, these highly detailed samples show all of the acorn nuts, jackscrew and alignment pins as well as the complete flush plan system. Very clean and super cool……..

Ameriflo uses very complex Computational Fluid Dynamics (CFD) software to engineer the maximum efficiency and hydraulic performance from every impeller that they manufacture. Solid Works software allows for the most efficient designing process currently available today. End suction (ES), vertical inline (VI), split case (SC) and vertical turbine (VT) product lines use these impellers as standard construction. The advantages of this engineering design and casting process are visible when you look at the performance curves offered by Ameriflo. Ameriflo leverages technology not available in the past to design and develop the most advanced product lines available in the market today.

Ameriflo uses very complex Computational Fluid Dynamics (CFD) software to engineer the maximum efficiency and hydraulic performance from every impeller that they manufacture. Solid Works software allows for the most efficient designing process currently available today. End suction (ES), vertical inline (VI), split case (SC) and vertical turbine (VT) product lines use these impellers as standard construction. The advantages of this engineering design and casting process are visible when you look at the performance curves offered by Ameriflo. Ameriflo leverages technology not available in the past to design and develop the most advanced product lines available in the market today.

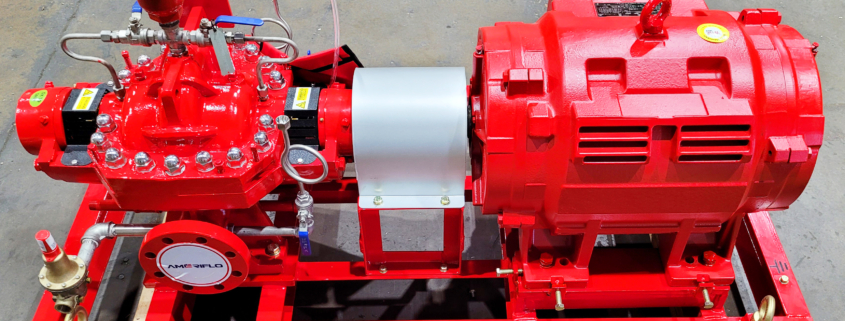

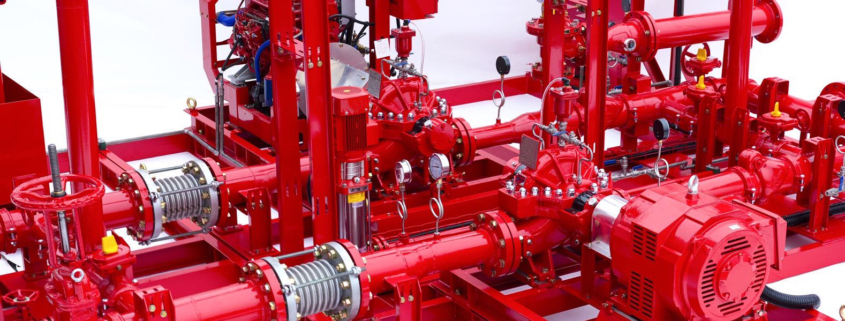

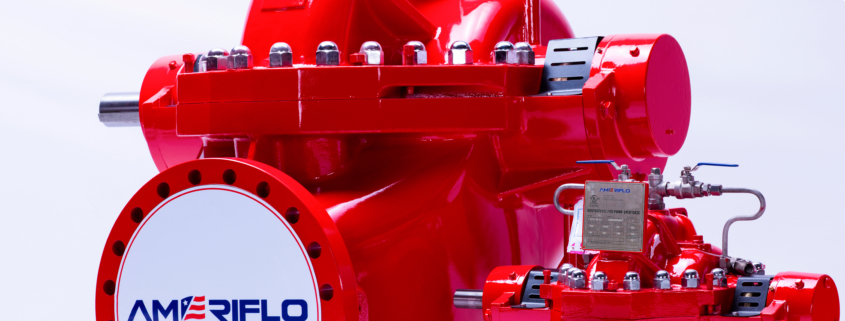

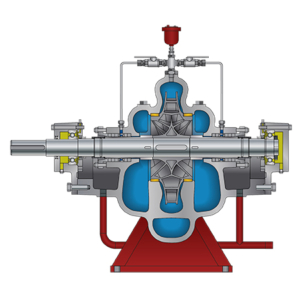

The SC product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo SC product line has the lowest documented horsepowers available in the fire protection market today!!

The SC product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo SC product line has the lowest documented horsepowers available in the fire protection market today!! All models feature investment cast, 304 stainless steel impellers and heavy wall, ribbed ductile iron casings. All shafts and shaft sleeves are offered standard in 420 stainless steel and feature unique and specifiable purge grease bearing lubrication. All inboard and outboard bearing housings are completely removable and replaceable without the need to remove the upper casing assembly. This allows for bearing inspection/replacement to be completed in a fraction of the time as compared to other manufacturers. Casing halves feature quadrant pry-bar locations with jack screws for easy casing disassembly when the need for service arises. Both stuffing box drip basins are also plumbed to a common point making the collection of packing leakage very clean at the job-site. Ameriflo is also one of the only manufacturers that mounts the pump data plate at a location where it is easily viewable, at the center of the upper casing assembly (where it should be).

All models feature investment cast, 304 stainless steel impellers and heavy wall, ribbed ductile iron casings. All shafts and shaft sleeves are offered standard in 420 stainless steel and feature unique and specifiable purge grease bearing lubrication. All inboard and outboard bearing housings are completely removable and replaceable without the need to remove the upper casing assembly. This allows for bearing inspection/replacement to be completed in a fraction of the time as compared to other manufacturers. Casing halves feature quadrant pry-bar locations with jack screws for easy casing disassembly when the need for service arises. Both stuffing box drip basins are also plumbed to a common point making the collection of packing leakage very clean at the job-site. Ameriflo is also one of the only manufacturers that mounts the pump data plate at a location where it is easily viewable, at the center of the upper casing assembly (where it should be).