Egyptian Fire Pumps

Electric & Diesel Driven Split Case Pumps

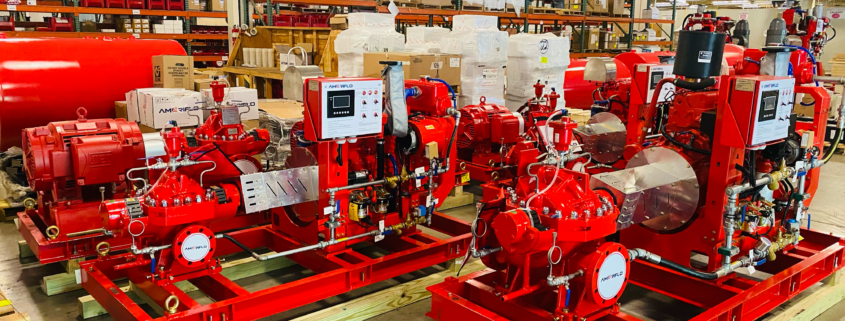

Ameriflo supplies equipment to nearly over 80 countries globally. Many of these applications use redundant electric, Diesel & jockey pump combinations (EDJ). These applications are a great example of how Ameriflo can control costs across the entire project as they are the only North American pump manufacturer to also manufacture their own Diesel engine product line. This gives the Ameriflo distributor an incredible advantage over their competition. The largest hydraulic coverage also allows for perhaps the best selections based on efficiency and speed.

Ameriflo supplies equipment to nearly over 80 countries globally. Many of these applications use redundant electric, Diesel & jockey pump combinations (EDJ). These applications are a great example of how Ameriflo can control costs across the entire project as they are the only North American pump manufacturer to also manufacture their own Diesel engine product line. This gives the Ameriflo distributor an incredible advantage over their competition. The largest hydraulic coverage also allows for perhaps the best selections based on efficiency and speed.

The pumps shown here are from the 5030 Series SC Split Case product line and cover 500, 750 & 100 GPM flows with pressures ranging from 5 to 10 bar. These pumps are coupled to WEG electric motors and Ameriflo Diesel engines. All pumps feature standard ductile iron casings, investment cast, 304 stainless steel impellers and are all mounted to the heavy duty Ameriflo fabricated base with alignment and leveling jackscrews standard.

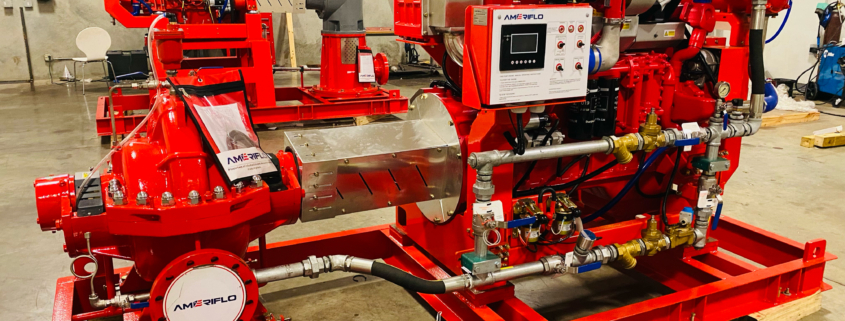

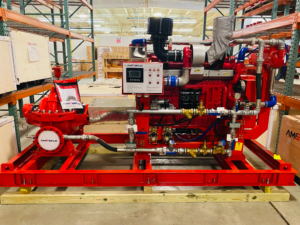

The pump featured in this short Blog includes a Diesel engine driven split case pump. This medium sized pump produces 2500 GPM @ 135 PSI. Ameriflo has the most efficient and expansive split case product offered in the fire protection market today. The 5030 SC product line has many standard features and benefits that are not offered even as options by the majority of the other players. The Diesel engine version features an Ameriflo AF6-135, 6 cylinder block generating 375 HP at 1760 RPM and has a large 1.500 inch cooling loop.

The pump featured in this short Blog includes a Diesel engine driven split case pump. This medium sized pump produces 2500 GPM @ 135 PSI. Ameriflo has the most efficient and expansive split case product offered in the fire protection market today. The 5030 SC product line has many standard features and benefits that are not offered even as options by the majority of the other players. The Diesel engine version features an Ameriflo AF6-135, 6 cylinder block generating 375 HP at 1760 RPM and has a large 1.500 inch cooling loop.

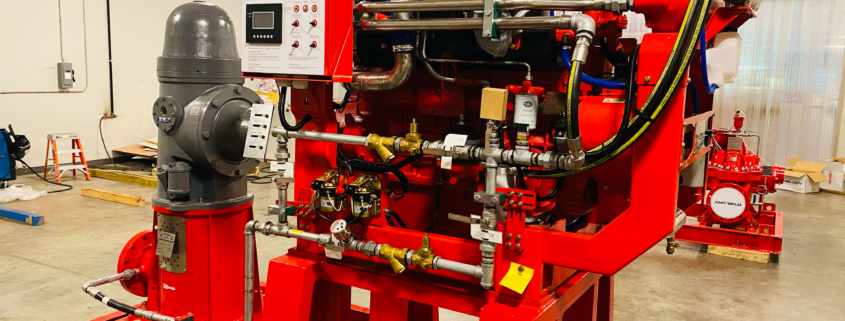

One of the most unique features of Ameriflo’s Diesel engine driven vertical turbine product line are the foundation bases. Every other vertical turbine manufacturer supplies a base for the discharge head only and has a separate base for the Diesel engine. The vertical offset between the Diesel engine and the pump is typically addressed at the job site by the contractor pouring the foundation. If ANY issue comes up during installation about the driveshaft not lining up with the right angle gear drive the finger pointing games kick off!! In the Ameriflo design, the foundation is flat, exactly the same when installing an end suction or split case. This vertical riser design is a game changer making Diesel engine vertical turbine installation a breeze.

One of the most unique features of Ameriflo’s Diesel engine driven vertical turbine product line are the foundation bases. Every other vertical turbine manufacturer supplies a base for the discharge head only and has a separate base for the Diesel engine. The vertical offset between the Diesel engine and the pump is typically addressed at the job site by the contractor pouring the foundation. If ANY issue comes up during installation about the driveshaft not lining up with the right angle gear drive the finger pointing games kick off!! In the Ameriflo design, the foundation is flat, exactly the same when installing an end suction or split case. This vertical riser design is a game changer making Diesel engine vertical turbine installation a breeze.