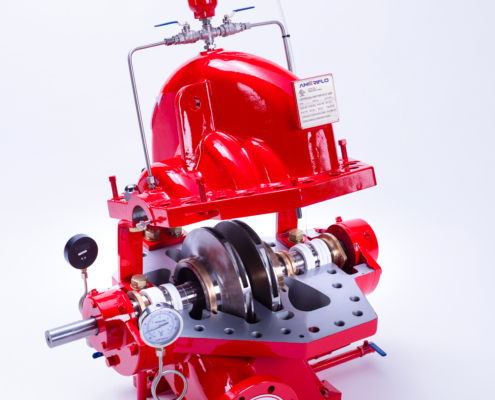

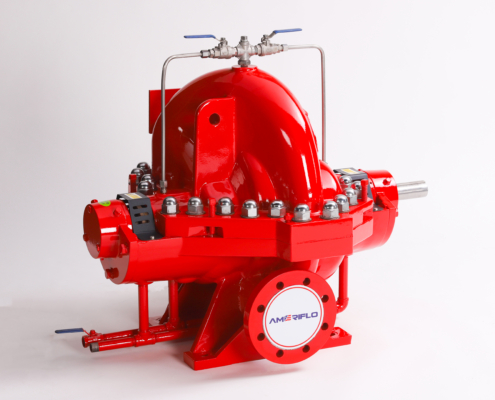

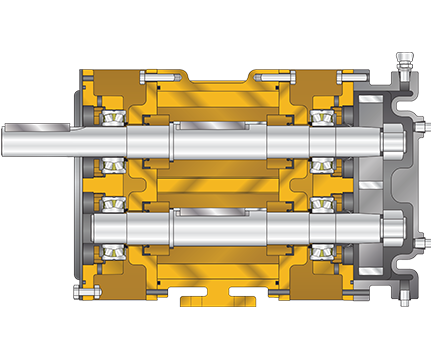

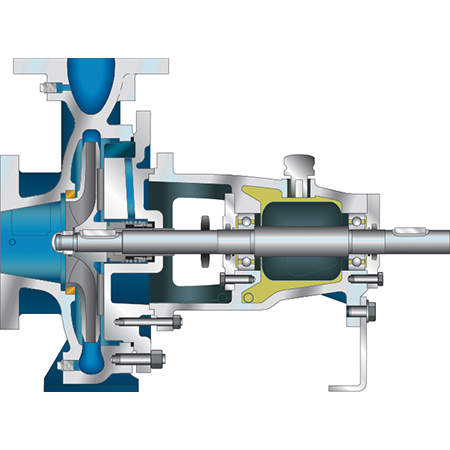

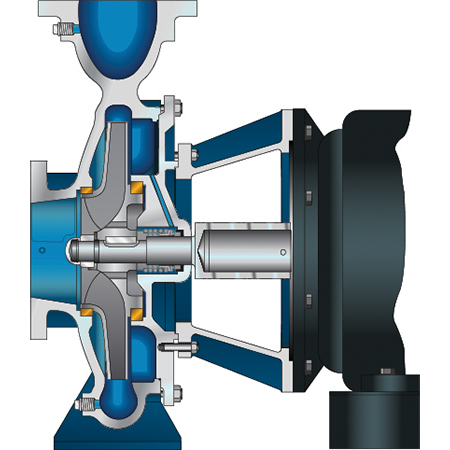

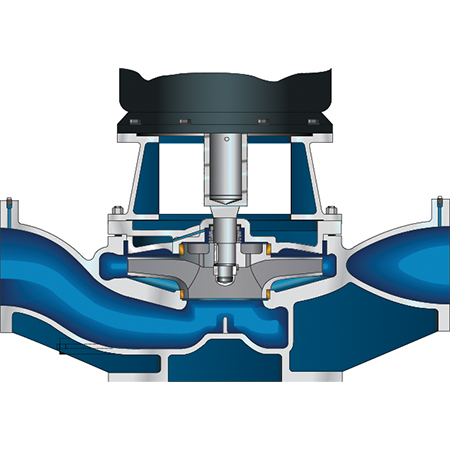

Ductile iron, double volute casing (on both stages) with investment cast 304SS impellers & 250# RF suction and discharge flanges

Horizontally split with pry-bar locations & jackscrews for easy rotor access

304 stainless steel acorn nuts fully enclose the casing studs to minimize corrosion

Proprietary Aegis buffer chamber that reduces the second stage stuffing box pressure to that of first stage

Rigid coupling guards are located at both stuffing box locations

Purge grease lubricated 6300 series, deep grove ball bearings at the inboard & outboard locations allowing bearing housing removal and replacement without complete pump disassembly

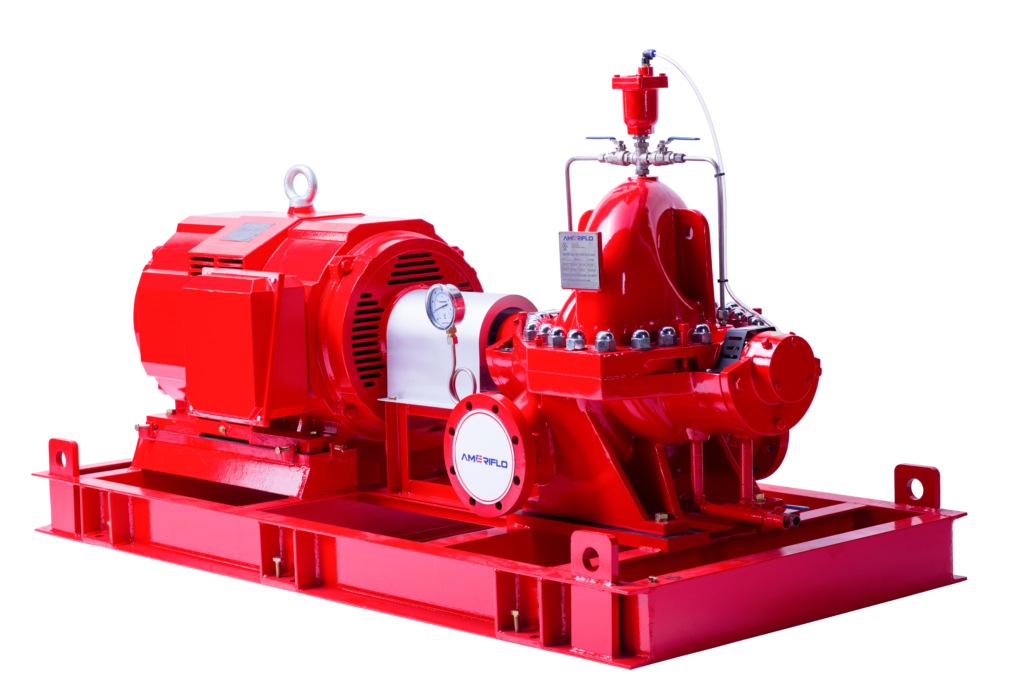

Dedicated ductile iron mounting plate bolted to put to easily view 304 stainless steel nameplate

All 304 stainless steel ball valves and flush tubing ensuring adequate lubrication to both stuffing boxes

304 stainless steel flush lines and ball valves provide lubrication to both stuffing boxes

Leakage from both stuffing boxes are plumbed to a single point making the connection to the drain very easy

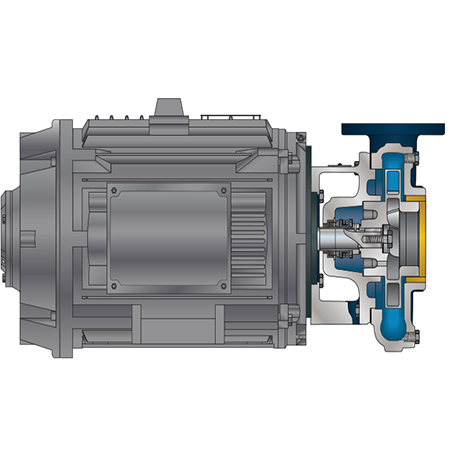

Milled and drilled pump pad locations to ensure complete contact and no soft foot issues

Rigid coupling guard completely surrounds the coupling and shaft

Fabricated base provided with jackscrews to aid in motor alignment

Integral grounding lug for the complete base assembly

Base jackscrews allow for very easy base leveling during installation

Integral lifting lugs to safely lift and move the complete base assembly

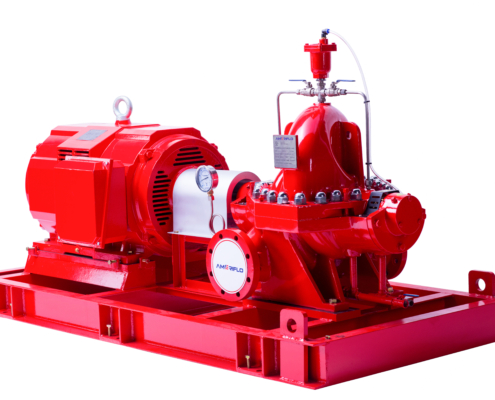

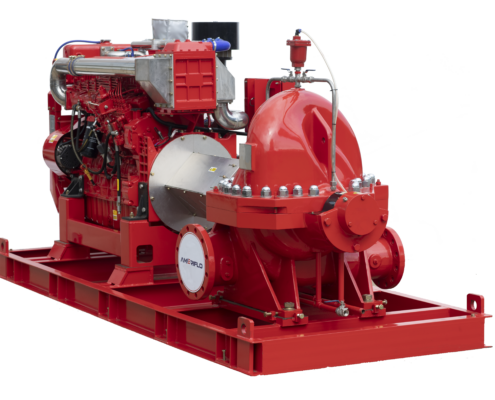

Electric motor or Diesel engine driver available

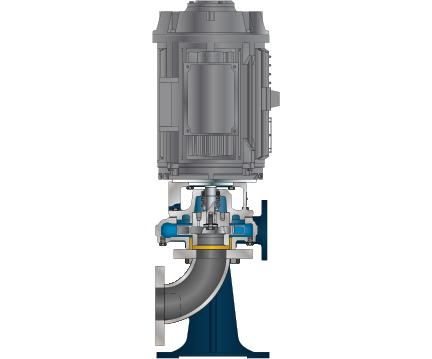

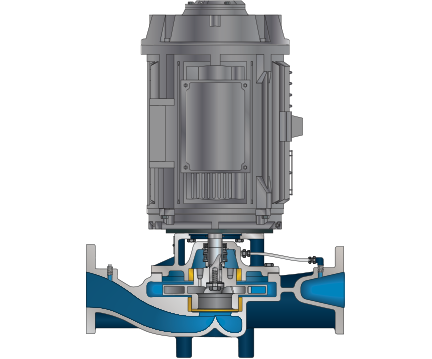

Series 5030 SC(2)

Multistage Split Case

FEATURES & BENEFITS

The Series 5030 SC(2) Multistage Split Case product line is a third party certified, fire protection pump in a flex-coupled orientation with an axially split casing assembly. This product can be electrically or Diesel engine driven and is a perfect fit for the smaller and larger flow applications found throughout the industry.

Certified Performance:

Flows: 500 GPM to 1,500 GPM [114 M3/HR to 341 M3/HR]

Heads: 282 PSI to 610 PSI [19.4 BAR to 42.1 BAR]

Speeds: 3550 RPM, 2950, 1760 RPM

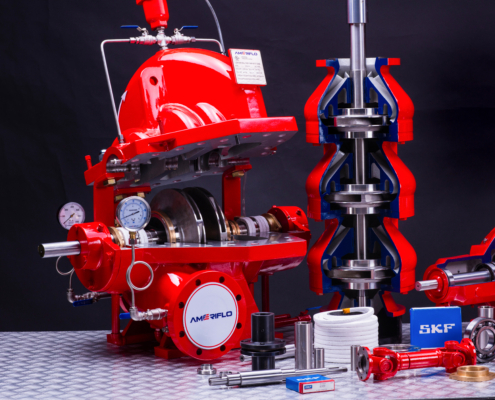

The 5030 Series SC(2) Multistage Split Case product line has the following specifiable features and benefits:

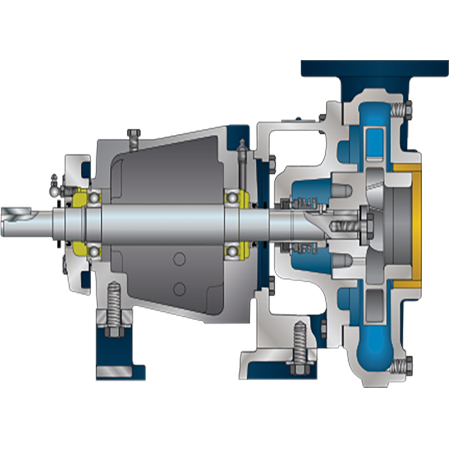

- Ductile iron, ribbed casing with 400 PSI pressure ratings

- Two-stage, double volute casing designed to reduce radial loads

- 250# RF suction & 250# RF discharge flanges

- High efficiency impeller design that leads the industry on lower horsepower

- Investment cast, 304 stainless steel impellers

- Proprietary Aegis buffer chamber that reduces pressure on second stage stuffing box

- 4340 quenched and tempered high chrome steel shafting

- 304 stainless steel shaft sleeves, 304 stainless steel glands and 304 stainless steel lantern rings

- 304 stainless steel flush lines with 304 stainless steel ball valves

- 6300 series deep groove bearing at the inboard and outboard locations

- Modular rotating assembly groups minimizes number of parts needed

- Inboard & outboard bearing housings are removable and replaceable without removing the casing top

- Casing top has pry bar locations and jackscrews to aid in pump disassembly

- Milled and drilled pad locations under pump and driver

- Alignment jackscrews located under the motor (Electric) or pump (Diesel) to aid in field alignment

- Base leveling jackscrews to allow for a quick and efficient leveling of the base to the concrete pad in the field

- Two grounding lugs located on the base to safely ground the entire assembly

- Integral lifting lugs on the base to safely lift and transport the entire base assembly