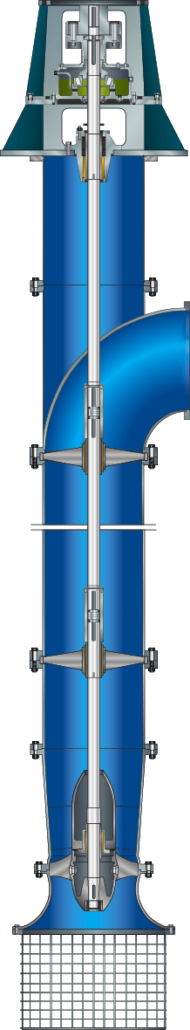

Strainer supplied standard in 304 stainless steel construction

Very large hydraulic offering with high flow rates

Axial Flow impellers constructed out of investment cast 304 stainless steel

420 stainless steel bowl shaft supplied standard

Unique sleeved bowl shaft completely protecting the shaft especially in bowl bearing locations

Fabricated, flanged, heavy wall column assemblies in sizes 4″ to 60″ diameter

Heavy duty fabricated steel discharge heads available in discharge sizes from 8″ to 60″ diameter

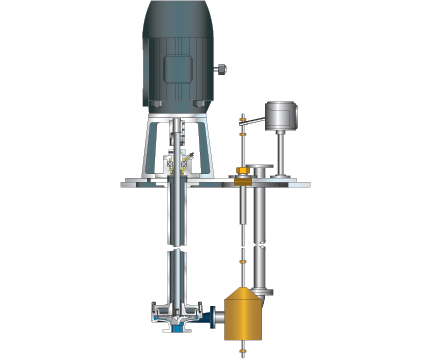

Optional oil lubricated thrust bearing stand

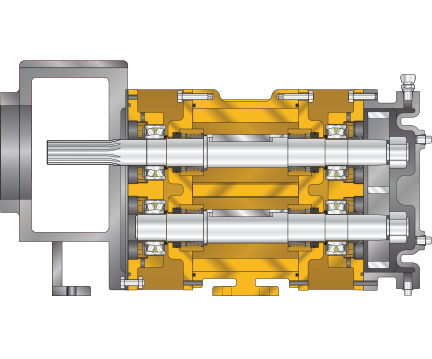

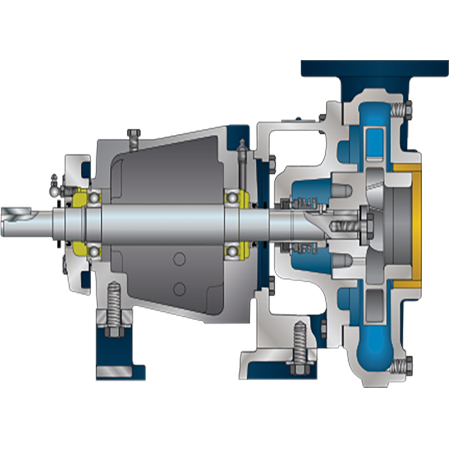

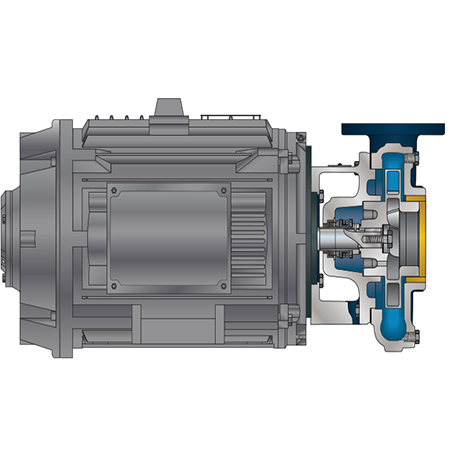

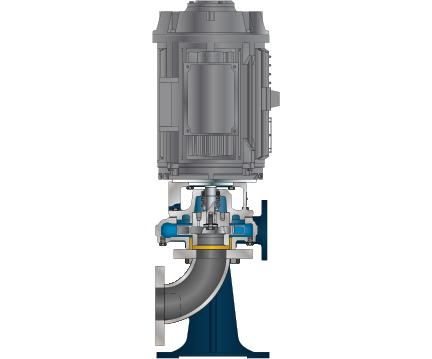

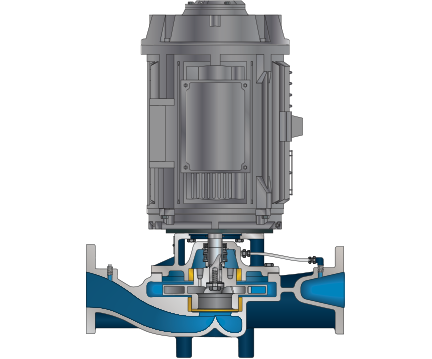

Series 4830

Axial Flow Pumps

FEATURES & BENEFITS

The Series 4830 AF Mixed Flow product line is a heavy duty mixed flow designed for the commercial, industrial & municipal markets. The AF Axial Flow product can be supplied for higher flow commercial & industrial applications. Pumps can be supplied in an overall length specified by the client. Optional material, packing or mechanical seal & thrust pot options are available upon request.

Certified Performance:

Flows: To 220,000 GPM [50,000 M3/HR]

Heads: To 50 FEET [15 M]

Speeds: 1760 RPM, 1480 RPM, 1180 RPM, 980 RPM, 740 RPM, 725 RPM, 590 RPM, 490 RPM, 380 RPM

Sizes: 12AF -> 74AF Bowls

The 4830 Series AF Axial Flow product line has the following specifiable features and benefits:

- Optional basket strainers in a variety of optional metallurgy

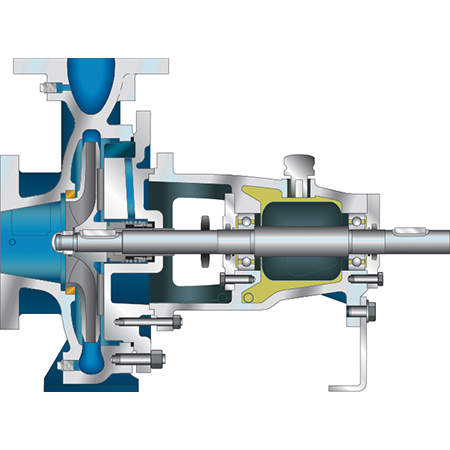

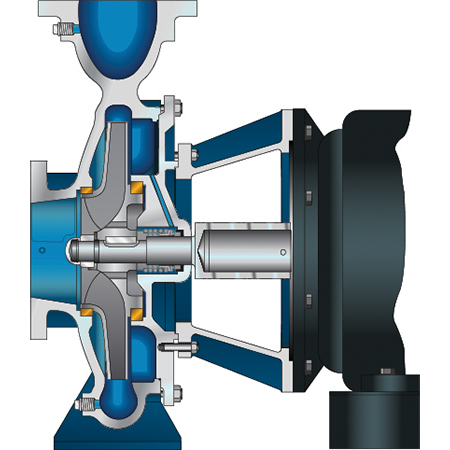

- Class 30 cast iron bowls

- Flanged bowl construction for easy assembly and disassembly

- Investment cast, 304 stainless steel propellers

- 4340 quenched and tempered high chrome steel shafting

- 304 stainless steel bolting

- Heavy duty bronze bowl bearings between each stage

- Flanged column assemblies (4″ through 48″) with 420 stainless steel line shaft

- Open or enclosed lineshaft construction available

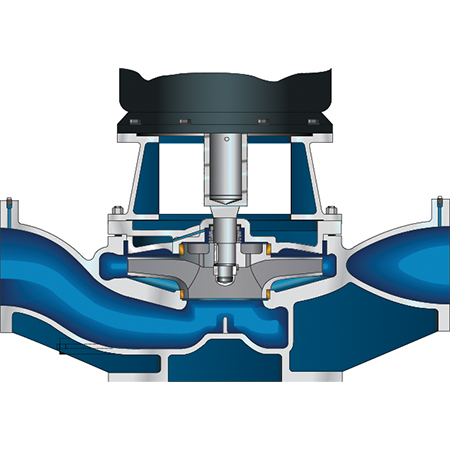

- Fabricated steel discharge heads (4″ through 48″) with heavy duty double bearing stuffing box assembly

- Stuffing box features 304 stainless steel shaft sleeves, 304 stainless steel gland & 304 stainless steel lantern ring

- Options for a wide variety of component & cartridge mechanical seals

- Full optional metallurgy support for seat water applications (all bronze, all 316SS, all 2205 & 2507 super duplex stainless steel)