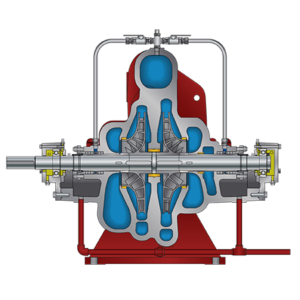

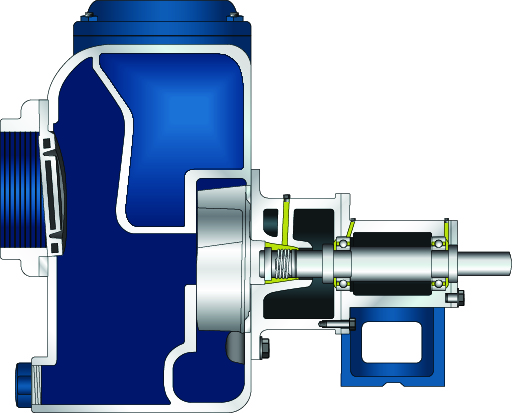

Check valve is oil resistant and canvas reinforced for long life

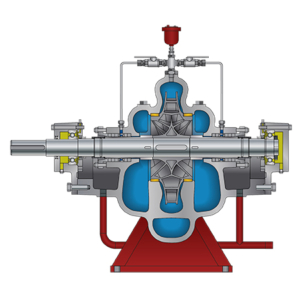

Two vane, non-clog solids handling impeller designed to pass large spherical solids

Ductile iron rear cover with packing, 304 SS sleeve & 304SS packing gland

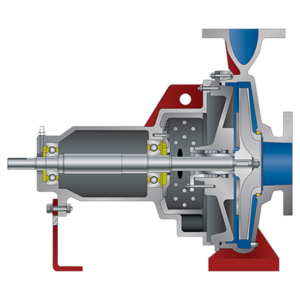

Class 30 cast iron power frame with 420SS shafting & 6300 series deep groove roller bearings

Tungsten Carbide versus Tungsten Carbide cartridge mechanical seal with 304 stainless steel shaft sleeve

Heavy wall, class 30 cast iron casing with removable cleanup plate and oversized fill port

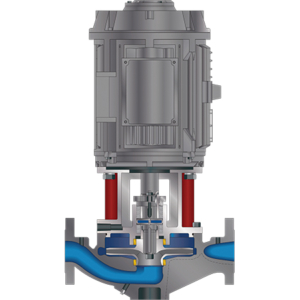

Oil reservoir lubricated the mechanical allowing it to run dry

Integral grounding lug for the complete base assembly

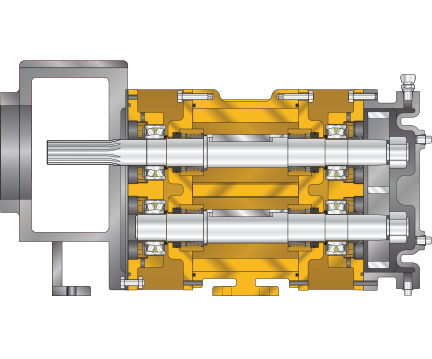

Power frame is back pull out allowing easy access to the entire rotor assembly

Power frame oil reservoir designed to lubricate the inboard and outboard bearings

Cleanout cover allows for removing debris from casing without removing the back pull out assembly

Suction check valve is removable and replaceable without disconnecting suction piping

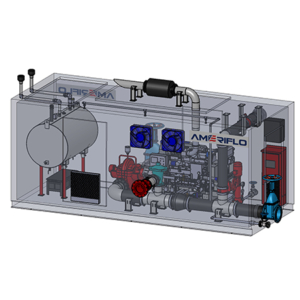

Series 4930 ALS

Flex-Coupled Trash Self-Primer Pumps

FEATURES & BENEFITS

The Series 4930 ALS Self-Primer product line is used in a variety of Commercial, Municipal & Indistrial applications where the supply of water is below the pump. This product can be electrically or Diesel engine driven and is a perfect fit for applications where pumping is required with solids present in the pumped fluid.

Certified Performance:

Flows: To 450 GPM [1454 M3/HR]

Heads: 140 Feet [61 M]

Speeds: Variable RPM

The 4930 Series ALS Self-Primer product line has the following specifiable features and benefits:

- Class 30 cast iron casing

- Full back pull out assembly is allows for the removal of the entire rotating assembly

- Two vane, solids passing impeller

- Large clean out plate on suction side of the pump allowing for full access to the impeller

- Class 30 cast iron, two vane, semi-open impeller

- 420 stainless steel shafting

- Hard face cartridge seal designed for aggressive fluids

- Grease lubricated mechanical seal chamber to allow for run-dry applications

- Grease lubricated bearing housing assembly

- Modular power frame assembly minimizes number of parts needed