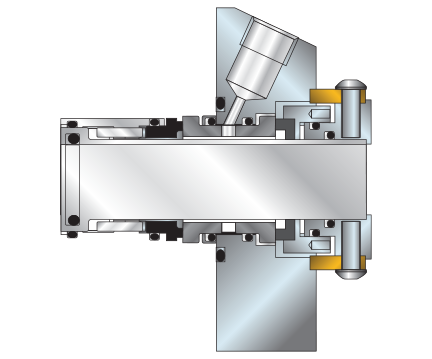

Carbon versus Silicon Carbide for primary & secondary faces with Viton elastomers

300 stainless steel hardware

1 inch to 4 inch size range

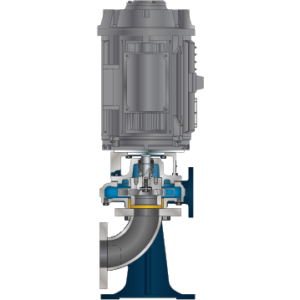

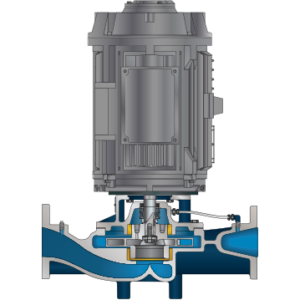

Inlet & outlet flush for adequate lubriction allowing the seal to be a primary (with backup) or tandem seal depending on flush conditions

Unique o-ring construction eliminates pumped fluid from contacting the milti-spring housing assembly

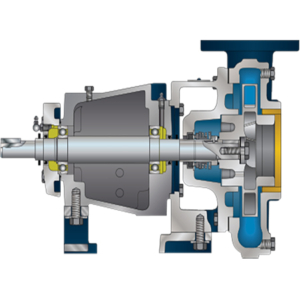

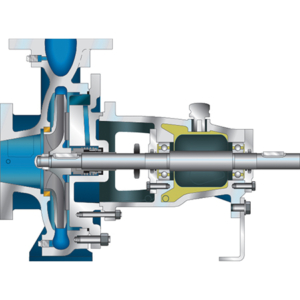

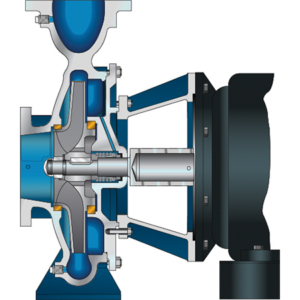

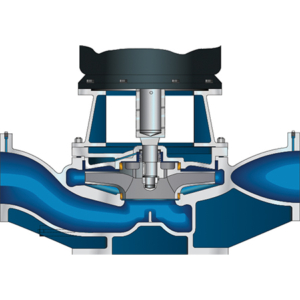

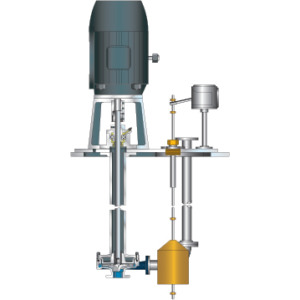

Series 8060

Double Cartridge Mechanical Seals

FEATURES & BENEFITS

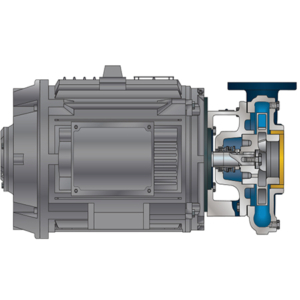

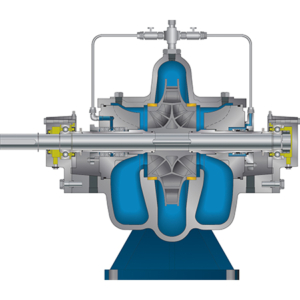

The Series 8060 Double Cartridge Mechanical Seal product line is used in a variety of Municipal & Industrial applications where the supply of water is faily clean and free of debris. This product can be used in a variety of process end suction and split case pumps.

Certified Performance:

Temperatures: -40 °F To 400 °F [-40 °C To 205 °C]

Pressures To: 425 PSI [29.3 Bar]

Speeds To: 4800 FPM [24.7 MPS]

The 8060 Single Cartridge Mechanical Seal product line has the following specifiable features and benefits:

- Carbon versus Silicon-Carbide primary & secondary faces

- Viton elastomers for large temperature range

- Unique o-ring design eliminates pumped fluid from contacting the multi-spring housing assembly

- 1.000 to 4.000 inch size range available

- Optional in 3610, 3620, 4610, 4810, 4820 & 4830 product lines