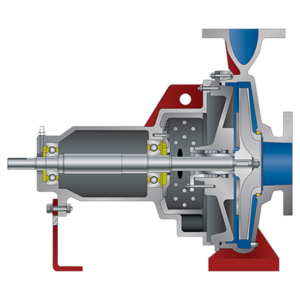

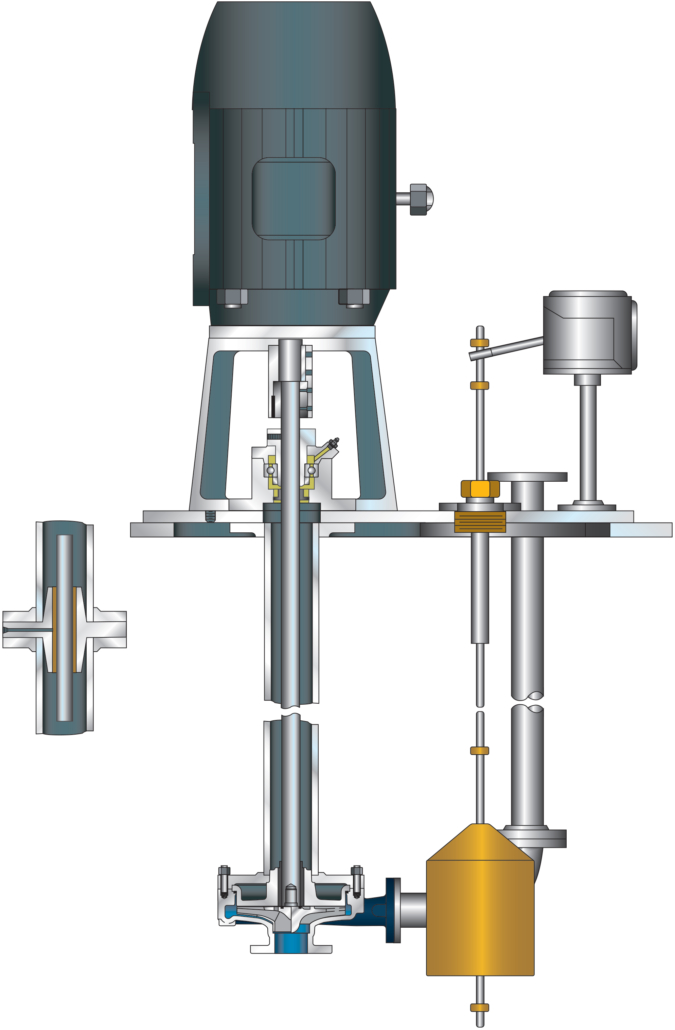

Ductile iron casing available in a wide variety of optional metallurgy based on job site requirements

Semi-open, investment cast 304 stainless steel impeller available in a wide variety of optional metallurgy based on job site requirements

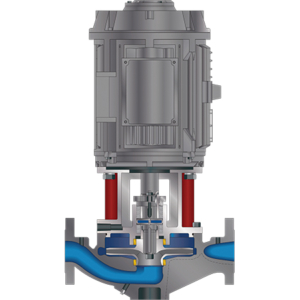

Fabricated steel column assemblies engineered to customer specified overall length

420 stainless steel shaft standard

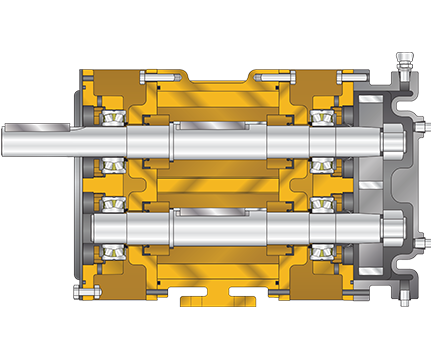

7300 series angular contact thrust bearing in a separate housing designed to withstand all axial forces generated by the pumping assembly

Standard, C-Face NEMA motors available in a wide variety of enclosures

Heavy duty bearing housing with bronze bearing externally drilled for optional flush

Parallel discharge pipe keeps contaminated fluid from lubricating column support bearings

Support plate can be engineered to meet job site requirements

Optional float switches available to meet job site requirements

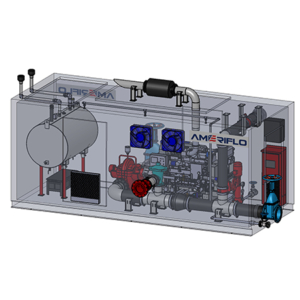

Duplex pump arrangements with man hole cover can be supplied upon request

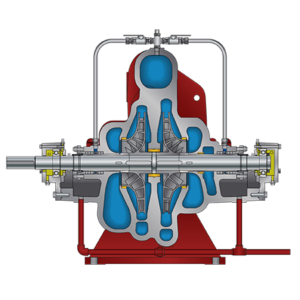

Series 3210 SAG

Vertical Sump Pumps

FEATURES & BENEFITS

The Series 3210 SAG Vertical Sump product line is used in a variety of Commercial, Municipal & Indistrial applications where the supply of water is below the pump. This pump features support column that does not use pumped fluid for bearing lubrication. The pump features a semi-open impeller that is good for clean and dirty fluids.

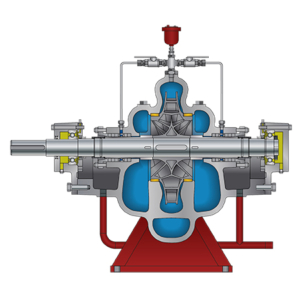

This product is designed for the process industry and is available in a with a wade variety of optional metallurgy available upon request.

Performance:

Flows: To 7,000 GPM [1,590 M3/HR]

Heads: To 730 Feet [223 Meters]

Sizes: 1.×1-6 To 8×10-15

Speeds: 3550 RPM, 2950 RPM, 1760 RPM, 1450 RPM, 1180 RPM, 980 RPM

The 3210 Series SAG Vertical sump product line has the following specifiable features and benefits:

- Ductile iron casing and rear cover with 125 PSI pressure ratings with a wade variety of optional metallurgy available upon request

- Centerline, high efficiency discharge casing

- 125# suction & 125# discharge flanges

- Semi-open, investment cast, 304 stainless steel impellers with a wade variety of optional metallurgy available upon request

- 420 stainless steel shafting

- 304 stainless steel shaft sleeve

- Optional external flush for column bearing lubrication

- Heavy duty, flanged support bearings

- Pump overall length can be customized based on job site requirements

- 7300 angular contact bearing located below the motor for complete rotor support

- Modular power frame assembly minimizes number of parts needed

- Variety of sump level controls available upon request