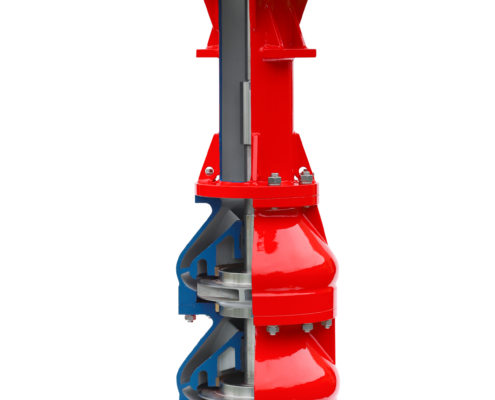

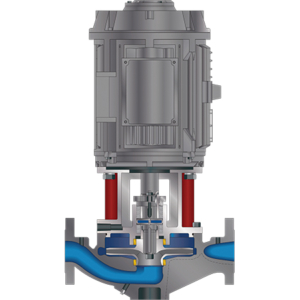

All bowl assemblies are supplied with a 304 stainless steel basket strainer

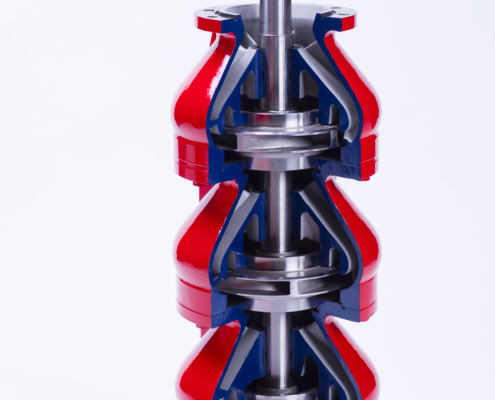

Bowl assemblies feature ductile iron construction with investment cast, 304 stainless steel impellers

Each stage features a double case wear ring design with impeller balancing holes to dramatically reduce axial thrust

All hardware is 304 stainless steel

Fabricated carbon steel discharge heads in 4″ through 16″ sizes with 250# RF flanges

Proprietary stuffing box with upper and lower 304 stainless steel shaft sleeves, 304 stainless steel gland assembly and 304 stainless steel lantern ring

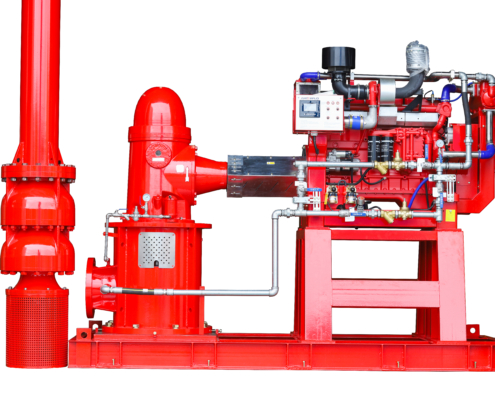

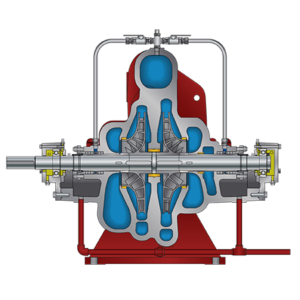

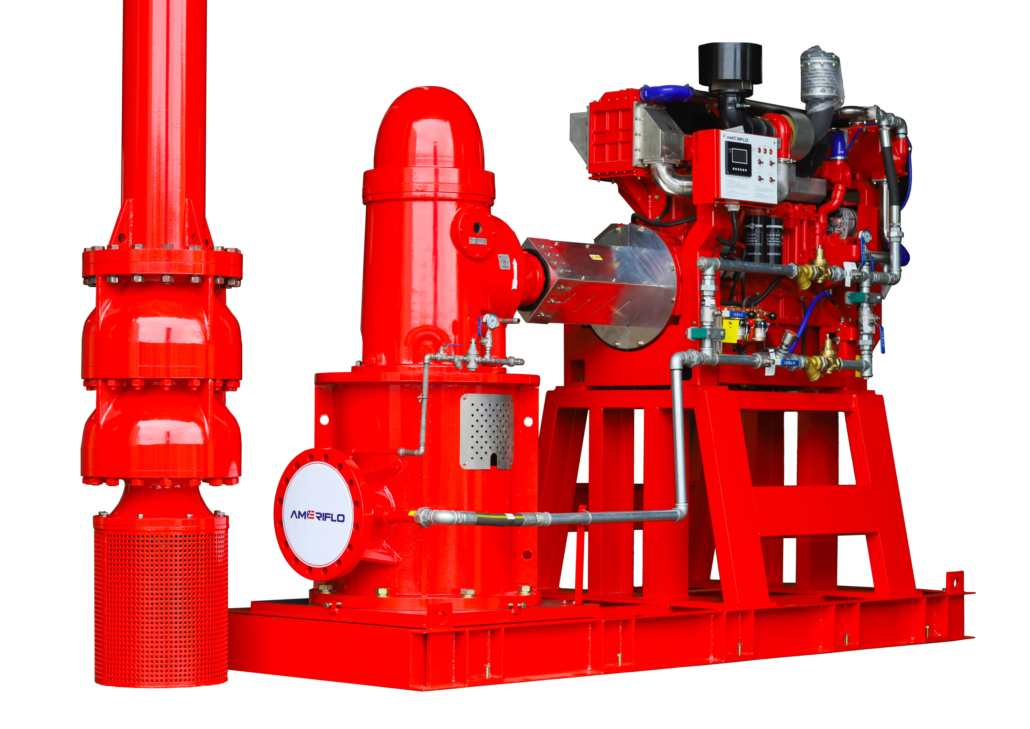

Supplied with an electric motor or right angle gear drive when a Diesel engine is supplied

When Diesel engine driven a right angle gear drive is supplied in a variety of gear ratios

Rigid coupling guard completely surrounds the coupling and shaft

Electric motor or Diesel engine driver available

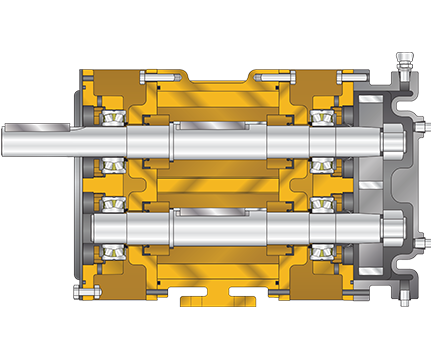

Base jackscrews allow for very easy base leveling during installation

Integral lifting lugs to safely lift and move the complete base assembly

Milled and drilled discharge head soleplate to ensure complete contact and no soft foot issues

When Diesel engine driven a single base is supplied making installation very simple as compared to applications where the pump and Diesel engine are mounted separately

When Diesel engine driven all Diesel engine and right angle gear drive cooling lines are plumbed

Integral grounding lug for the complete base assembly

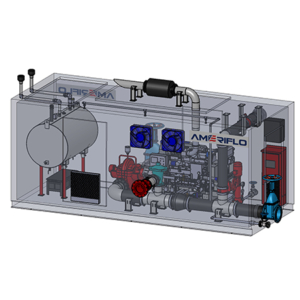

Series 5040

Vertical Turbine Pumps

FEATURES & BENEFITS

The Series 5040 VT Vertical Turbine product line is a third party certified, fire protection pump in an overall length vertical turbine assembly. This product can be electrically or Diesel engine driven and is a perfect fit for applications where a wet well is present at the job-site.

Certified Performance:

Flows: 100 GPM to 7,500 GPM [22.7 M3/HR to 1,703 M3/HR]

Heads: 40 PSI to 377 PSI [2.75 BAR to 26.0 BAR]

Speeds: 2950 RPM, 1760 RPM, 1480 RPM

The 5040 Series VT Vertical Turbine product line has the following specifiable features and benefits:

- Ductile iron bowls with double wear ring construction

- Flanged bowl construction with jackscrew threads for easy assembly and disassembly

- Hydraulically balanced, investment cast, 304 stainless steel impellers with lower and upper bowl wear rings

- 4340 quenched and tempered high chrome steel shafting

- 304 stainless steel shaft sleeves between each stage and under each bowl bearing

- 304 stainless steel basket strainer

- Heavy duty bronze bowl bearings between each stage

- Flanged column assemblies (4″, 6″, 8″, 10″, 12″, 14″, & 16″) with 420 stainless steel line shaft

- Fabricated steel discharge heads (4″, 6″, 8″, 10″, 12″, 14″, & 16″) with heavy duty double bearing stuffing box assembly

- Stuffing box features 304 stainless steel shaft sleeves, 304 stainless steel gland & 304 stainless steel lantern ring

- Full optional metallurgy support for sea water applications (all bronze, all 2205 & all 2507 super duplex stainless steel)

- Milled and drilled pad locations under pump and driver

- Alignment jackscrews located under the motor (Electric) or pump (Diesel) to aid in field alignment

- Base leveling jackscrews to allow for a quick and efficient leveling of the base to the concrete pad in the field

- Two grounding lugs located on the base to safely ground the entire assembly

- Integral lifting lugs on the base to safely lift and transport the entire base assembly