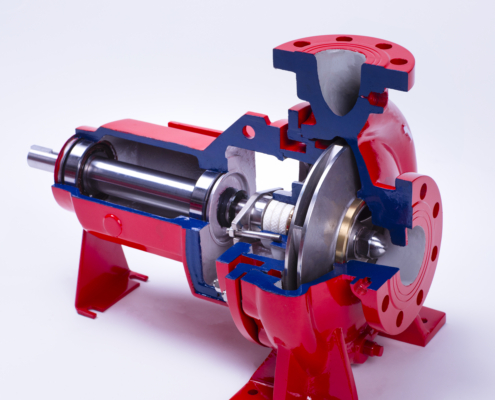

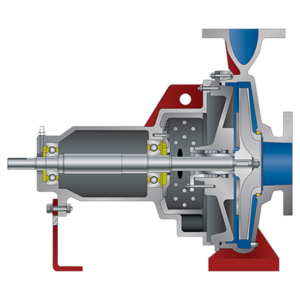

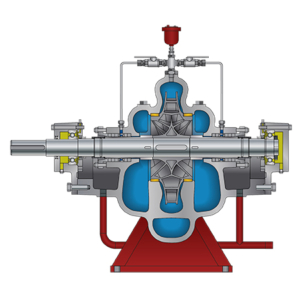

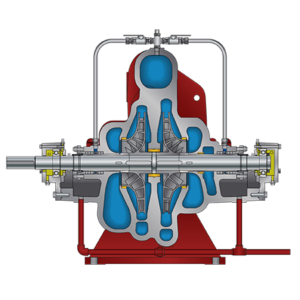

Ductile iron, centerline discharge casing with investment cast 304SS impeller & 250# RF suction and discharge flanges

Cast integral feet with support during removal of back-pull out assembly

Ductile iron rear cover with packing, 304 SS sleeve & 304SS packing gland

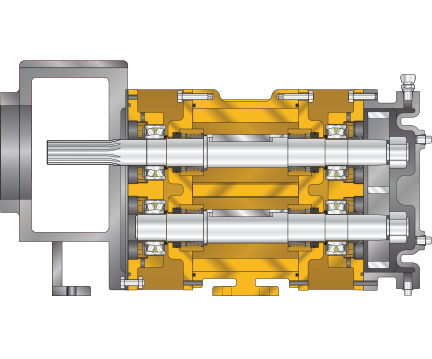

Class 30 cast iron power frame with 420SS shafting & 7300 series angular contact bearings

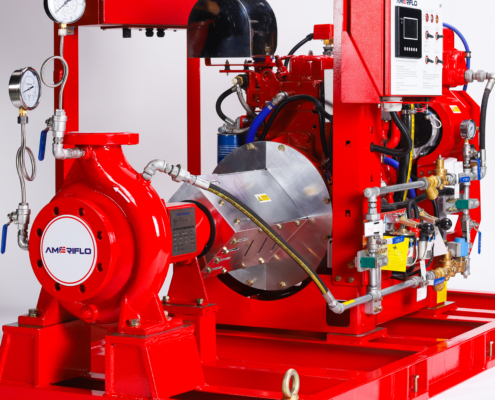

Dedicated ductile iron mounting plate bolted to put to easily view 304 stainless steel nameplate

304SS safety guards completely isolate packing housing chamber

Rigid coupling guard completely surrounds the coupling and shaft

Electric motor or Diesel engine driver available

Integral grounding lug for the complete base assembly

Integral lifting lugs to safely lift and move the complete base assembly

Base jackscrews allow for very easy base leveling during installation

Fabricated base provided with jackscrews to aid in motor alignment

Milled and drilled pump pad locations to ensure complete contact and no soft foot issues

Suction and discharge locations provided with 304 stainless buffer tubing with 304 stainless steel ball valves

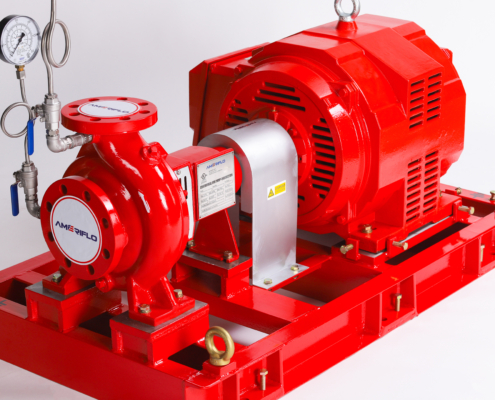

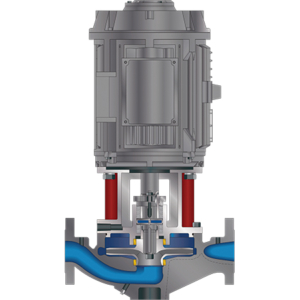

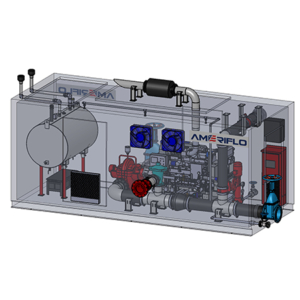

Series 5010 ES

Flex-Coupled End Suction Pumps

FEATURES & BENEFITS

The Series 5010 ES End Suction product line is a third party certified, fire protection pump in a flex-coupled orientation with a centerline discharge. This product can be electrically or Diesel engine driven and is a perfect fit for the smaller flow applications found throughout the industry.

Certified Performance:

Flows: 50 GPM to 2,000 GPM [11 M3/HR to 455 M3/HR]

Heads: 40 PSI to 220 PSI [2.75 BAR to 15.2 BAR]

Speeds: 3550 RPM, 2950 RPM

The 5010 Series ES End Suction product line has the following specifiable features and benefits:

- Ductile iron casing and rear cover with 250 PSI pressure ratings

- Cast integral casing foot that provides casing support when the back pull out assembly is removed

- Centerline discharge minimizes residual piping strain and is self venting

- Cast integral vortex suppressor located at suction inlet designed to minimize pre-rotation of fluid prior to entering the impeller eye

- 250# RF suction & 250# RF discharge flanges

- Investment cast, 304 stainless steel impellers

-

- 4340 quenched and tempered high chrome steel shafting

- 304 stainless steel shaft sleeve, 304 stainless steel gland and 304 stainless steel lantern ring

- 304 stainless steel flush lines with 304 stainless steel ball valves

- 7300 series angular contact bearing at the inboard and outboard locations

- Modular power frame assembly minimizes number of parts needed

- Milled and drilled pad locations under pump and driver

- Alignment jackscrews located under the motor (Electric) or pump (Diesel) to aid in field alignment

- Base leveling jackscrews to allow for a quick and efficient leveling of the base to the concrete pad in the field

- Two grounding lugs located on the base to safely ground the entire assembly

- Integral lifting lugs on the base to safely lift and transport the entire base assembly