5020 Series Vertical Inline

Ameriflo is excited to announce the final stages of their newest product offering, the 5020 VI Vertical Inline product line. This product line will be the most advanced and hydraulically efficient Vertical Inline product available for the Fire Protection industry. The Ameriflo distributor network has asked about the product line for the last three months and today we will take a sneak peak of what is to come.

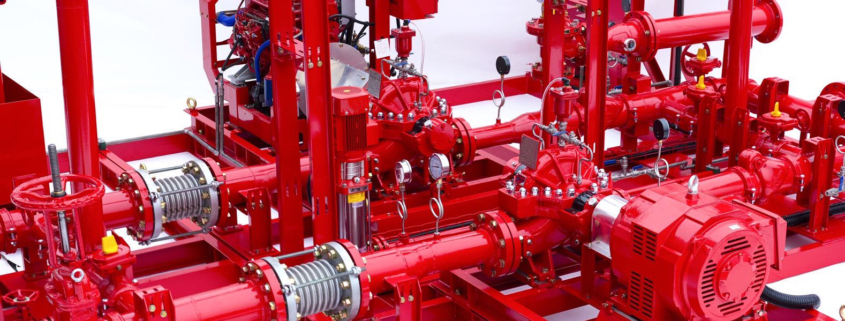

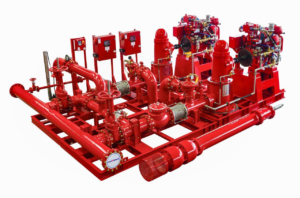

The VI product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo VI product line has the lowest documented horsepowers available in the fire protection market today!!

The VI product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo VI product line has the lowest documented horsepowers available in the fire protection market today!!

Performance Characteristics

- Sizes: 2×2-8 to 6×6-13

- Flows: 50 to 1,500 GPM

- Pressures: 40 to 198 PSI

- Frequencies: 50 & 60 Cycle

- Speeds: 3550, 2950,1760 & 1450 RPM

The 5020 VI product line is coupled to a NEMA C-Face, JP Frame motor. This allows for a very compact footprint as well as a diverse horsepower coverage. Ameriflo VI Vertical Inline products are available from a very small 10 HP all the way up to 250 HP. This allows for one of the most diverse hydraulic coverages available from any vertical inline Fire Pump manufacturer.

Read more

The VI product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo VI product line has the lowest documented horsepowers available in the fire protection market today!!

The VI product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo VI product line has the lowest documented horsepowers available in the fire protection market today!!

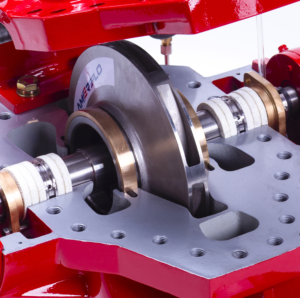

Ameriflo uses very complex Computational Fluid Dynamics (CFD) software to engineer the maximum efficiency and hydraulic performance from every impeller that they manufacture. Solid Works software allows for the most efficient designing process currently available today. End suction (ES), vertical inline (VI), split case (SC) and vertical turbine (VT) product lines use these impellers as standard construction. The advantages of this engineering design and casting process are visible when you look at the performance curves offered by Ameriflo. Ameriflo leverages technology not available in the past to design and develop the most advanced product lines available in the market today.

Ameriflo uses very complex Computational Fluid Dynamics (CFD) software to engineer the maximum efficiency and hydraulic performance from every impeller that they manufacture. Solid Works software allows for the most efficient designing process currently available today. End suction (ES), vertical inline (VI), split case (SC) and vertical turbine (VT) product lines use these impellers as standard construction. The advantages of this engineering design and casting process are visible when you look at the performance curves offered by Ameriflo. Ameriflo leverages technology not available in the past to design and develop the most advanced product lines available in the market today.