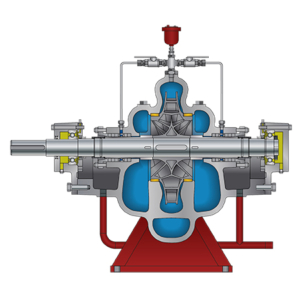

5030 Series SC Single Stage Split Case

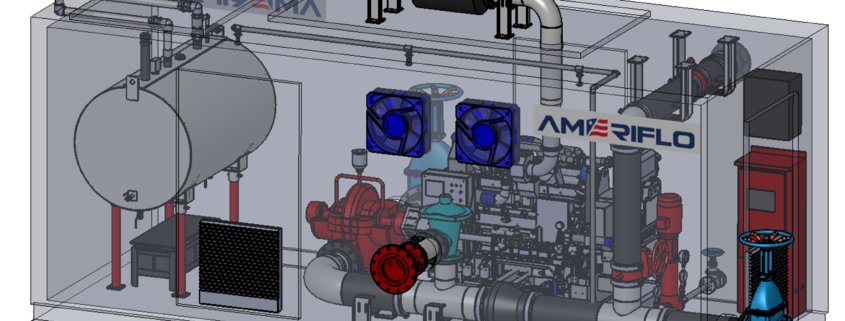

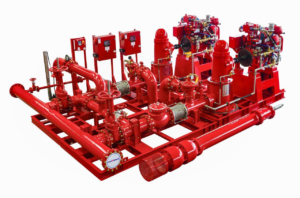

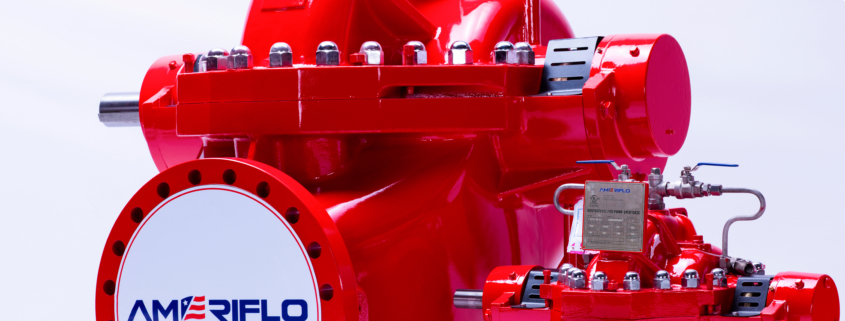

Ameriflo has many different product lines that cover many different markets. Perhaps the most popular product offered today by Ameriflo is the split case product line. Ameriflo has the largest, third party certified hydraulic coverage as compared to any other current North American manufacturer. The 5030 Series SC product line is available in a single stage and a two stage design. Todays blog will focus on the single stage design and a future blog will focus on the two-stage.

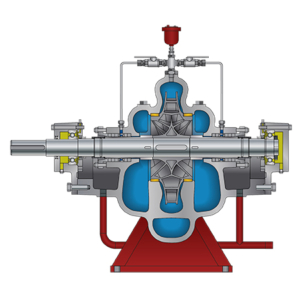

The SC product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo SC product line has the lowest documented horsepowers available in the fire protection market today!!

The SC product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo SC product line has the lowest documented horsepowers available in the fire protection market today!!

Performance Characteristics

- Sizes: 3×5-8 to 12×16-30

- Flows: 300 to 8,000 GPM

- Pressures: 40 to 367 PSI

- Frequencies: 50 & 60 Cycle

- Speeds: 3550, 2950, 2600, 2350, 2100, 2000, 1760 & 1450 RPM

The 5030 Series SC product line has third party flow rates starting at 300 GPM and stopping at an incredible 8,000 GPM, much, much larger than nearly all other NFPA 20 centrifugal pump manufacturers. This extended range allows Ameriflo to offer a single fire pump in an application where other manufacturers must offer two or more units. This gives the client an incredible amount of flexibility when it comes to installation cost and footprint required.

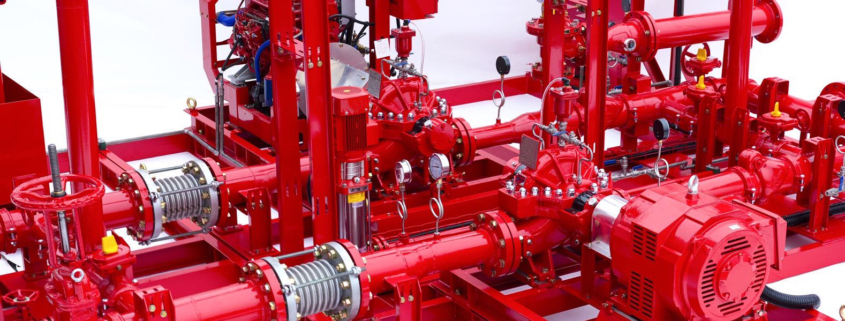

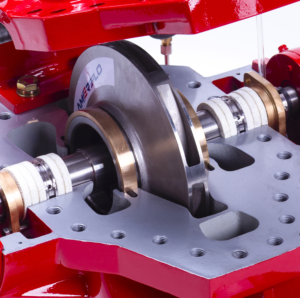

All models feature investment cast, 304 stainless steel impellers and heavy wall, ribbed ductile iron casings. All shafts and shaft sleeves are offered standard in 420 stainless steel and feature unique and specifiable purge grease bearing lubrication. All inboard and outboard bearing housings are completely removable and replaceable without the need to remove the upper casing assembly. This allows for bearing inspection/replacement to be completed in a fraction of the time as compared to other manufacturers. Casing halves feature quadrant pry-bar locations with jack screws for easy casing disassembly when the need for service arises. Both stuffing box drip basins are also plumbed to a common point making the collection of packing leakage very clean at the job-site. Ameriflo is also one of the only manufacturers that mounts the pump data plate at a location where it is easily viewable, at the center of the upper casing assembly (where it should be).

All models feature investment cast, 304 stainless steel impellers and heavy wall, ribbed ductile iron casings. All shafts and shaft sleeves are offered standard in 420 stainless steel and feature unique and specifiable purge grease bearing lubrication. All inboard and outboard bearing housings are completely removable and replaceable without the need to remove the upper casing assembly. This allows for bearing inspection/replacement to be completed in a fraction of the time as compared to other manufacturers. Casing halves feature quadrant pry-bar locations with jack screws for easy casing disassembly when the need for service arises. Both stuffing box drip basins are also plumbed to a common point making the collection of packing leakage very clean at the job-site. Ameriflo is also one of the only manufacturers that mounts the pump data plate at a location where it is easily viewable, at the center of the upper casing assembly (where it should be).

All pumps have suction and discharge gauges installed with 304 stainless steel buffer tubing (for stable pressure readings) as well as 304 stainless steel ball valves. All internal flush tubing and all ball valves present on the upper casing are also constructed out of 304 stainless steel. Lastly, each stuffing box is protected by a power coated, metal safety guard keeping safety a paramount priority.

Read more

Ameriflo uses very complex Computational Fluid Dynamics (CFD) software to engineer the maximum efficiency and hydraulic performance from every impeller that they manufacture. Solid Works software allows for the most efficient designing process currently available today. End suction (ES), vertical inline (VI), split case (SC) and vertical turbine (VT) product lines use these impellers as standard construction. The advantages of this engineering design and casting process are visible when you look at the performance curves offered by Ameriflo. Ameriflo leverages technology not available in the past to design and develop the most advanced product lines available in the market today.

Ameriflo uses very complex Computational Fluid Dynamics (CFD) software to engineer the maximum efficiency and hydraulic performance from every impeller that they manufacture. Solid Works software allows for the most efficient designing process currently available today. End suction (ES), vertical inline (VI), split case (SC) and vertical turbine (VT) product lines use these impellers as standard construction. The advantages of this engineering design and casting process are visible when you look at the performance curves offered by Ameriflo. Ameriflo leverages technology not available in the past to design and develop the most advanced product lines available in the market today.

The SC product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo SC product line has the lowest documented horsepowers available in the fire protection market today!!

The SC product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo SC product line has the lowest documented horsepowers available in the fire protection market today!! All models feature investment cast, 304 stainless steel impellers and heavy wall, ribbed ductile iron casings. All shafts and shaft sleeves are offered standard in 420 stainless steel and feature unique and specifiable purge grease bearing lubrication. All inboard and outboard bearing housings are completely removable and replaceable without the need to remove the upper casing assembly. This allows for bearing inspection/replacement to be completed in a fraction of the time as compared to other manufacturers. Casing halves feature quadrant pry-bar locations with jack screws for easy casing disassembly when the need for service arises. Both stuffing box drip basins are also plumbed to a common point making the collection of packing leakage very clean at the job-site. Ameriflo is also one of the only manufacturers that mounts the pump data plate at a location where it is easily viewable, at the center of the upper casing assembly (where it should be).

All models feature investment cast, 304 stainless steel impellers and heavy wall, ribbed ductile iron casings. All shafts and shaft sleeves are offered standard in 420 stainless steel and feature unique and specifiable purge grease bearing lubrication. All inboard and outboard bearing housings are completely removable and replaceable without the need to remove the upper casing assembly. This allows for bearing inspection/replacement to be completed in a fraction of the time as compared to other manufacturers. Casing halves feature quadrant pry-bar locations with jack screws for easy casing disassembly when the need for service arises. Both stuffing box drip basins are also plumbed to a common point making the collection of packing leakage very clean at the job-site. Ameriflo is also one of the only manufacturers that mounts the pump data plate at a location where it is easily viewable, at the center of the upper casing assembly (where it should be).