Intersec 2023

The 24th edition of Intersec will unite the industry and accelerate conversations to explore strategies and source technologies for the challenges faced by global security leaders and professionals.

Bringing you representation from over 50 countries with 10+ official international country pavilions including the United States, Canada, France, United Kingdom, Germany, South Africa, Czech Republic, Turkey, China, Singapore, Italy, and more; this is your unique opportunity to connect, network, source, and succeed in business face-to-face with global suppliers from across the world.

Be a part of the success story, share and gain insights, knowledge, and solutions as we once again gather and reconnect with existing clients and build new partnerships. We are excited to host you and look forward to reinforcing those ever important business relationships that are the pinnacle of every exhibition. The show floor will be buzzing with all that is new from Ameriflo, product demos, learning opportunities and the most recent updates from Ameriflo. Ameriflo will be showing the latest in pump tech including proprietary designs and advanced manufacturing techniques. Stop by and get the latest information on Ameriflo and their plans on market dominance……

Read more

It’s always great to be Number 1 and so will be the case with the new Ameriflo Global Headquarters located in Piperton, TN. The city has graciously given the address, #1 Ameriflo Circle, that only suits what Ameriflo has been doing on the global stage. These images show the extensive facility (and the quite honestly the seriousness Ameriflo has in the future) that is currently being designed and constructed in Western Tennessee. As seen in previous posts, this facility will house senior management, production, engineering, sales and service schools resources, all hydraulic and Diesel engine testing, as well as the complete manufacturing facility for all Ameriflo product lines.

It’s always great to be Number 1 and so will be the case with the new Ameriflo Global Headquarters located in Piperton, TN. The city has graciously given the address, #1 Ameriflo Circle, that only suits what Ameriflo has been doing on the global stage. These images show the extensive facility (and the quite honestly the seriousness Ameriflo has in the future) that is currently being designed and constructed in Western Tennessee. As seen in previous posts, this facility will house senior management, production, engineering, sales and service schools resources, all hydraulic and Diesel engine testing, as well as the complete manufacturing facility for all Ameriflo product lines.

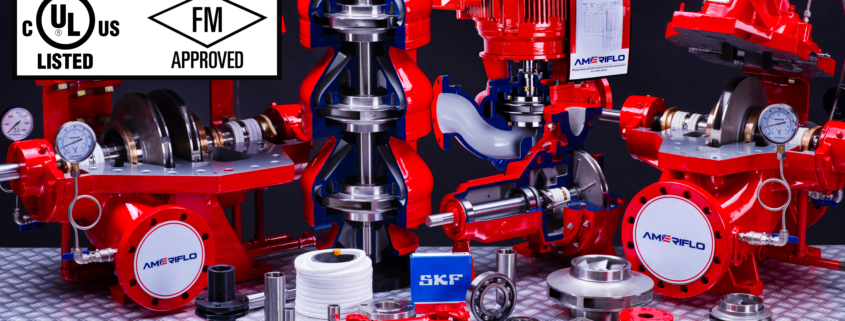

Ameriflo started its global program by first focusing on fire protection. Over the last several years, Ameriflo has developed and released the most comprehensive UL & FM fire protection offering on the planet. With complete coverage in the end suction, vertical inline, split case and vertical turbine, our hydraulics are unmatched. Couple that with the only pump manufacturer offered Diesel engine program and you have a very dangerous product offering that has disrupted the global fire protection market.

Ameriflo started its global program by first focusing on fire protection. Over the last several years, Ameriflo has developed and released the most comprehensive UL & FM fire protection offering on the planet. With complete coverage in the end suction, vertical inline, split case and vertical turbine, our hydraulics are unmatched. Couple that with the only pump manufacturer offered Diesel engine program and you have a very dangerous product offering that has disrupted the global fire protection market.

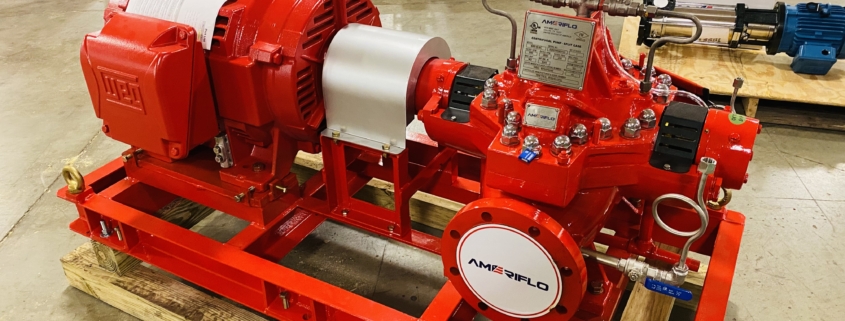

Can you say THREE DAY LEAD-TIME!! Another Express Quick Ship package out the door by the end of the week. This is an emergency shipment for a high rise building in NY City. The client was on Fire Watch and paying nearly $3,000 a day while waiting for a competitor pump that was quoted with an 11 week lead-time. They knew this 11 week time-frame would get drawn out to 20 weeks or more.

Can you say THREE DAY LEAD-TIME!! Another Express Quick Ship package out the door by the end of the week. This is an emergency shipment for a high rise building in NY City. The client was on Fire Watch and paying nearly $3,000 a day while waiting for a competitor pump that was quoted with an 11 week lead-time. They knew this 11 week time-frame would get drawn out to 20 weeks or more.

5010 End Suction Performance Characteristics

5010 End Suction Performance Characteristics

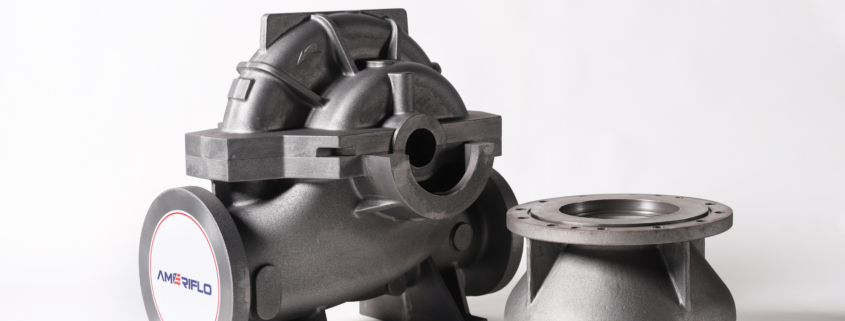

For some reason, many people forget about end suction pumps when it comes to Fire Protection. This product type is VERY popular outside of the United States. The 5010 ES product line has current coverage through 1250 GPM with an expansion through 2500 GPM currently in engineering.

For some reason, many people forget about end suction pumps when it comes to Fire Protection. This product type is VERY popular outside of the United States. The 5010 ES product line has current coverage through 1250 GPM with an expansion through 2500 GPM currently in engineering.

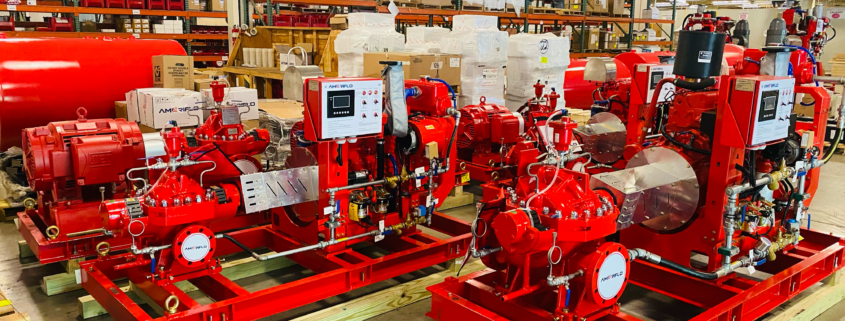

Ameriflo supplies equipment to nearly over 80 countries globally. Many of these applications use redundant electric, Diesel & jockey pump combinations (EDJ). These applications are a great example of how Ameriflo can control costs across the entire project as they are the only North American pump manufacturer to also manufacture their own Diesel engine product line. This gives the Ameriflo distributor an incredible advantage over their competition. The largest hydraulic coverage also allows for perhaps the best selections based on efficiency and speed.

Ameriflo supplies equipment to nearly over 80 countries globally. Many of these applications use redundant electric, Diesel & jockey pump combinations (EDJ). These applications are a great example of how Ameriflo can control costs across the entire project as they are the only North American pump manufacturer to also manufacture their own Diesel engine product line. This gives the Ameriflo distributor an incredible advantage over their competition. The largest hydraulic coverage also allows for perhaps the best selections based on efficiency and speed.